3D printing

My experience with 3D printing

Regarding the Ultimate Rapi-Meeting-Room project, the 3D printing case was perfomed by a service provider via FDM technology (Fused Deposition Modeling). The result seemed fairly average to me, in any case lacking in precision and above all a lot of streaks marking the different layers. But that was about 2 years ago and I know that 3D printers have evolved very quickly.

For this project, I asked myself whether it was appropriate to take the plunge and the opportunity to acquire a 3D printer. My constraints were as follows:

- the price: I did not have the ambition to produce prints every WE and it was therefore somewhat of a gadget

- the size: I live in an apartment and do not have a DIY workshop or a similar room

- the precision: cases are small or medium size and the fixings are at 1/10 millimeters

- the instantaneous quality: again, I do not have a workshop and therefore cannot consider sanding parts in my apartment

The fruit of my research led me to SLA (Stereolitography) printers. And after hours of consulting comparison sites and tests videos, I turned to an Elegoo Saturn for the size of its platform – it should be noted that at the end of December 2020, this one was expected by all aficionados and that I was fortunate enough to be able to order the last few pieces of a lot of 200 that went on sale only a few minutes before I clicked the button. Lucky!

I make it short, but I deliver my verdict after several dozen impressions:

- the Elegoo Saturn presents an undeniable quality vs price ratio. It is very precise as long as onpowering orientation, exposure times and supports size and placement. Not all resins are created equal, but when it comes to technical parts, I recommend Elegoo’s (transparent) red photopolymer precisely for its precision and resistance (rigidity over time).

- we do not print in SLA as in FDM and certainly not like a sheet of paper from a laser printer. What I mean is that there are steps, protocol and extra-time, assuming:

- a well ventilated room during and after printing because the vapors are harmful (I experienced a headache and fever after my first impression).

- suitable material: disposable gloves (after each printing), protective mask (I did not hesitate after my first disappointment to invest in a mask for harmful paints), protective overall, filters to recover the resin remaining from the tank, paper towels for cleaning tank, tray and other tools, etc … this represents a budget and also a certain amount of time after each printing

- bottles of IPA (Isopropyl) alcohol to clean the parts after printing and a UV exposure kit to complete the light-curing.

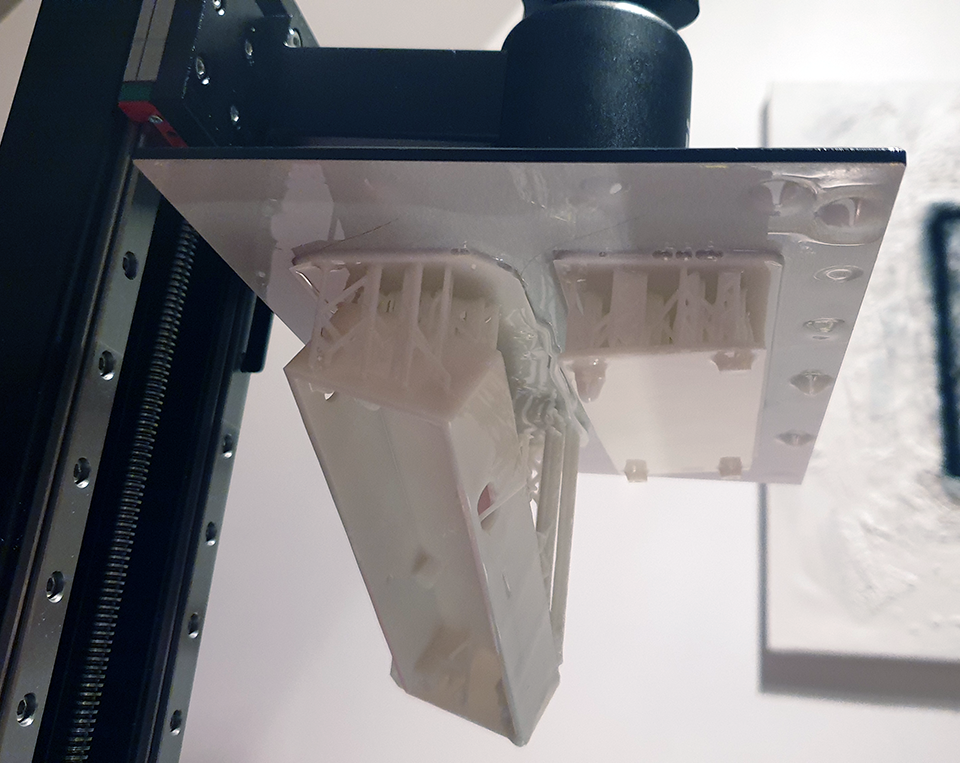

- Finally, I still have to go to my balcony to sand the parts because the supports leave traces that should be removed

… in fact it’s work but it’s not a simple and quick operation. Anyway, expected result is there; just like precision, mainly (and perhaps oddly) on parts with small dimensions

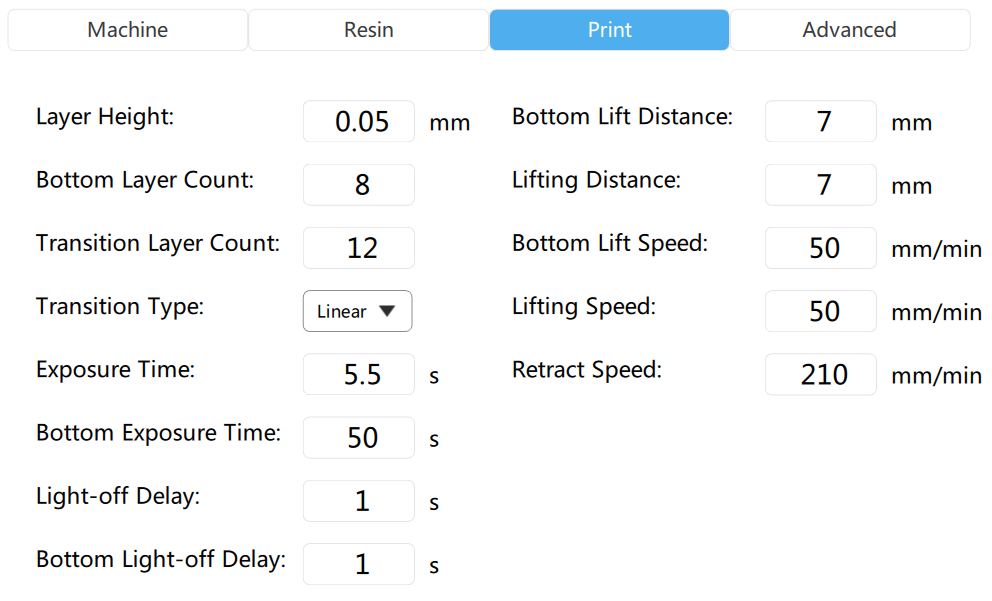

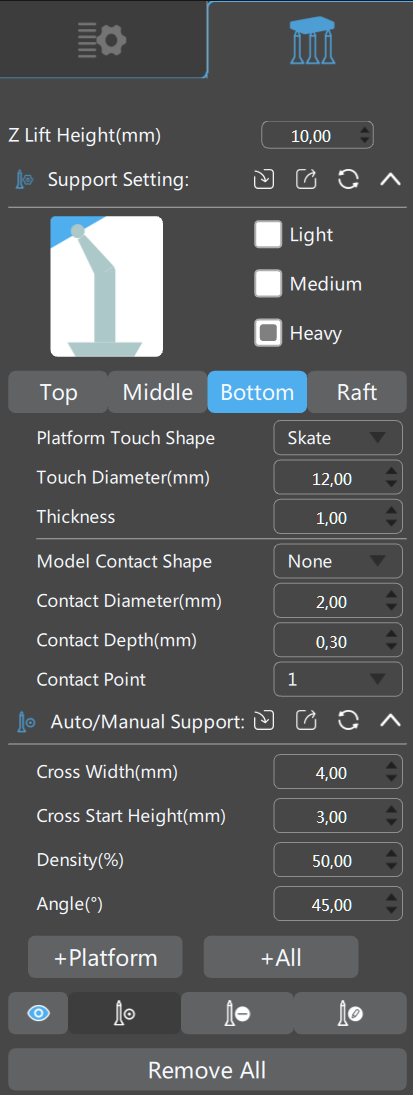

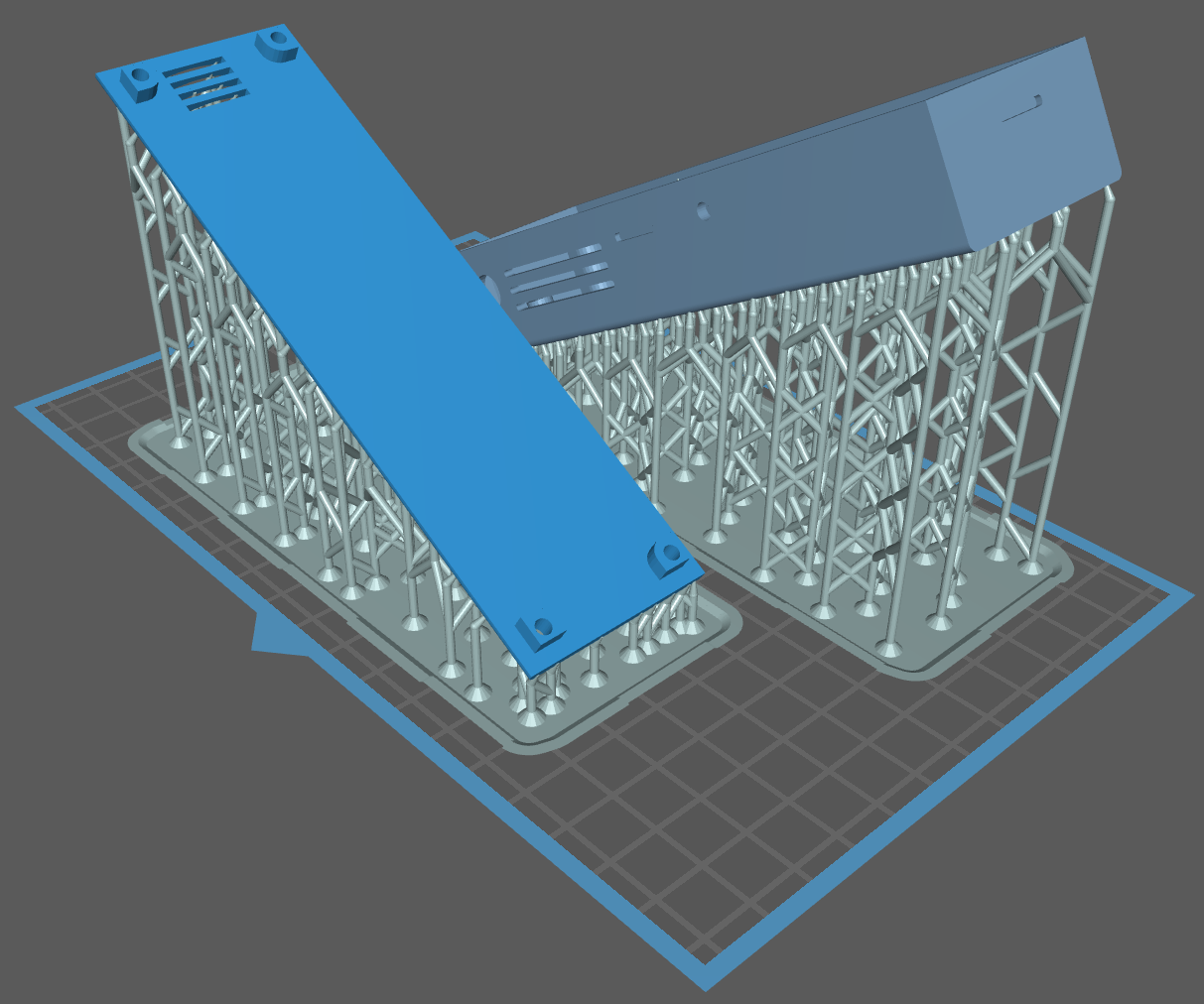

Finding the right exposure times, the density and the positionning of the supports and the parts orientations (30° looks fine) is not so easy. So, we might as well share what works well. I use CHITUBOX. I also recommand Elegoo facebook groups as ELEGOO SATURN 3D printer Owners (English speaking) as well as ELEGOO SATURN FRANCE and ELEGOO MARS/SATURN (both French speaking) which helped me a lot while I was facing discouraging issues.

3D designing

No need to get lost in blabla…just Scketchup ! File here.

Once tamed, it’s a treat (even if I still moan sometime).

I recommend installing the Solid Inspector 2 plug-in and using it all along of the design to make sure groups and components are ‘SOLID’; otherwise, it is not possible to export a printable .STL file, and it is better to detect a possible fault early enough rather than to spend hours breaking out everything to start again. Also, think about making use of the layers (renamed to Tags) this in order to isolate the parts.

Next … export STL files for each parts-body, cover, mounting and import into a slicer, e.g. CHITUBOX or LycheeSlicer